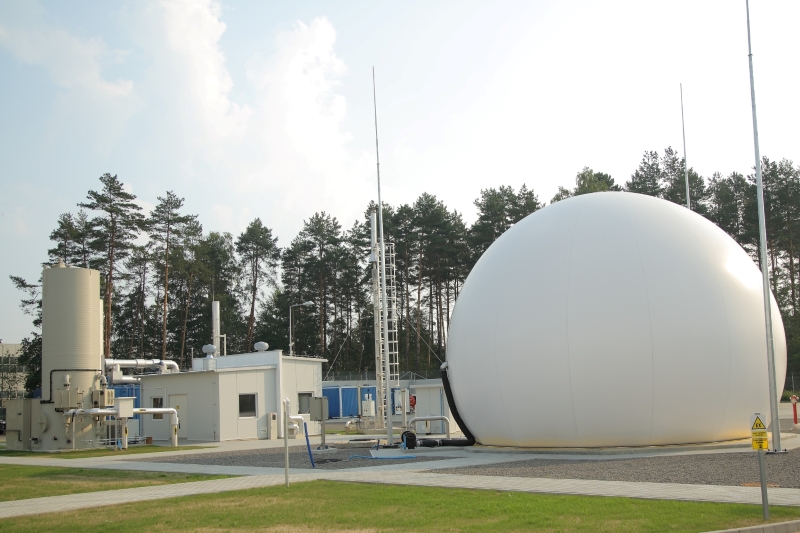

Environmental protection

Environmental protection is our passion, and ensuring safety and comfort for communities is our priority. We implement projects that ensure the purity of water, safety of waste and stability of the environment. We build new facilities and modernize existing ones, adapting them to individual needs of our clients. We cooperate with subsidiaries of local and central administration units, municipal associations, and private investors.