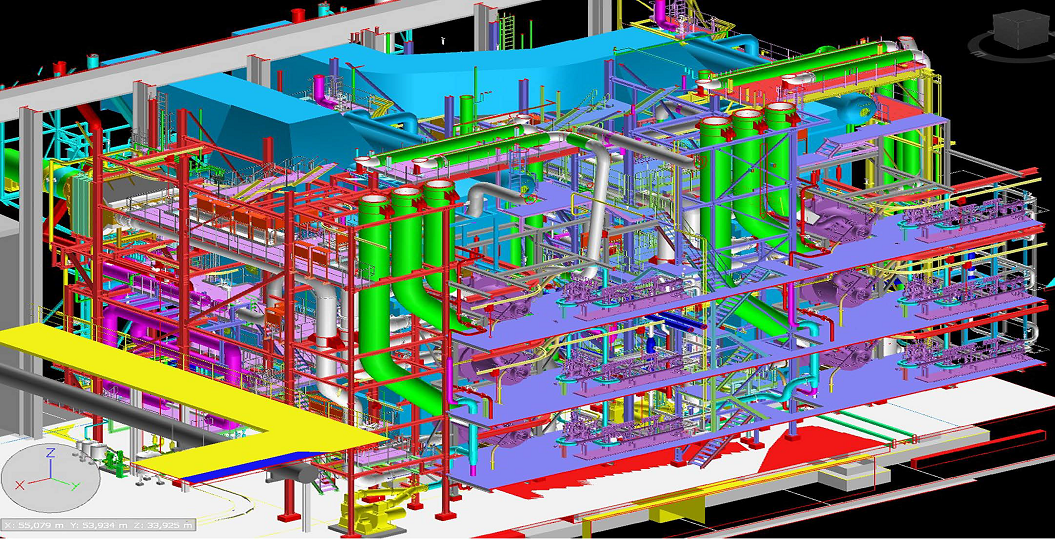

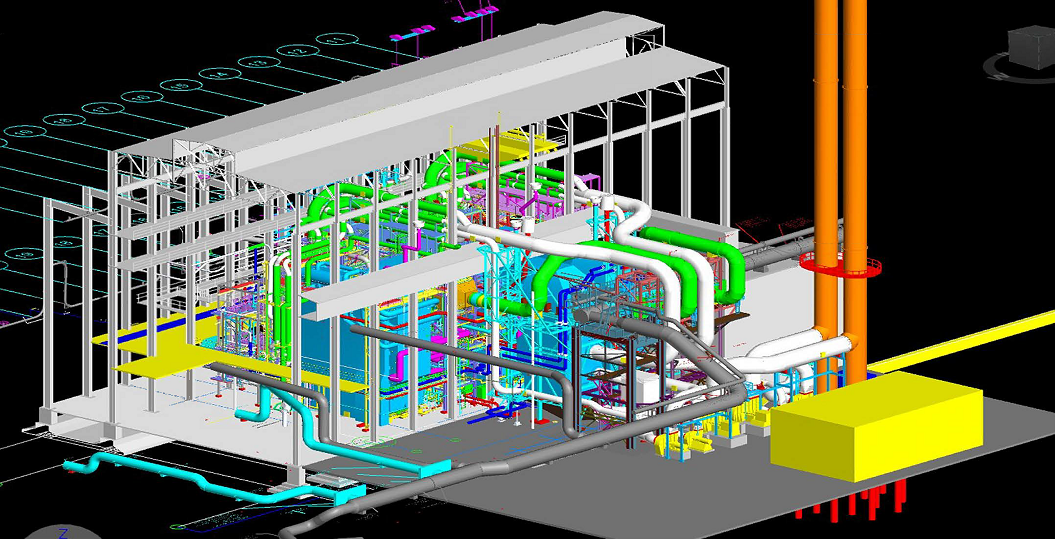

Boiler island ZW Kraków

Construction of a gas-fired power unit fired by blast furnace gas and natural gas with a total electric power of 55 MW.

Construction of a gas-fired power unit fired by blast furnace gas and natural gas with a total electric power of 55 MW.

ZW Kraków is a thermal power plant producing utilities for ArcelorMittal Poland S.A. plants located in Kraków. The construction of new 150 t/h gas-fired boilers fired by blast furnace gas, coke oven gas and natural gas is expected to contribute to the complete elimination of hard coal from the combustion process.

The scope of the task will include the construction of a boiler island based on two gas-fired boilers with a capacity of 150 t/h of heated steam, each with a pressure of 9 MPa and a temperature of 540° C.

The purpose of this investment is to meet new environmental requirements under the EU Industrial Emissions Directive. As a result of the investment, emissions of sulfur and nitrogen compounds as well as dust into the atmosphere will be significantly reduced. Dust emissions are to be reduced by 90%, nitrogen oxides by 83%, sulfur dioxide by 80%, carbon monoxide by 40%, and carbon dioxide by 20%.

As part of the implementation of the task, built :

– two steam boilers,

– fresh steam pipelines,

– feed water pipelines,

– pipelines for fuel supply to the boiler: blast furnace gas, natural gas and coke oven gas,

– auxiliary plant pipelines (nitrogen, desalination, drainage and drainage, compressed air),

– air and flue gas ducts,

– two steel chimneys with a height of 67m,

– natural gas supply system with SRP station.

Limiting the use of hard coal in such a large industrial plant located in the city has resulted in a reduction in the emission of harmful dust and gases into the atmosphere, which is important for air quality in Krakow, an agglomeration that has been struggling with the problem of PM 10 and PM 2.5 particulate matter for years.

In addition to environmental aspects, thanks to the application of the latest technological solutions, the energy efficiency of the plant has also increased, reducing its operating costs. Boiler efficiency has improved by 10%, and power generation has increased by more than 10%.